Phenolic Board

Phenolic boards, a composite of cellulose fibers and phenolic resin, excel in durability, moisture resistance, and fire retardancy. Widely used in construction, transportation, and marine industries, they embody strength and reliability, meeting stringent quality standards in Europe and America.

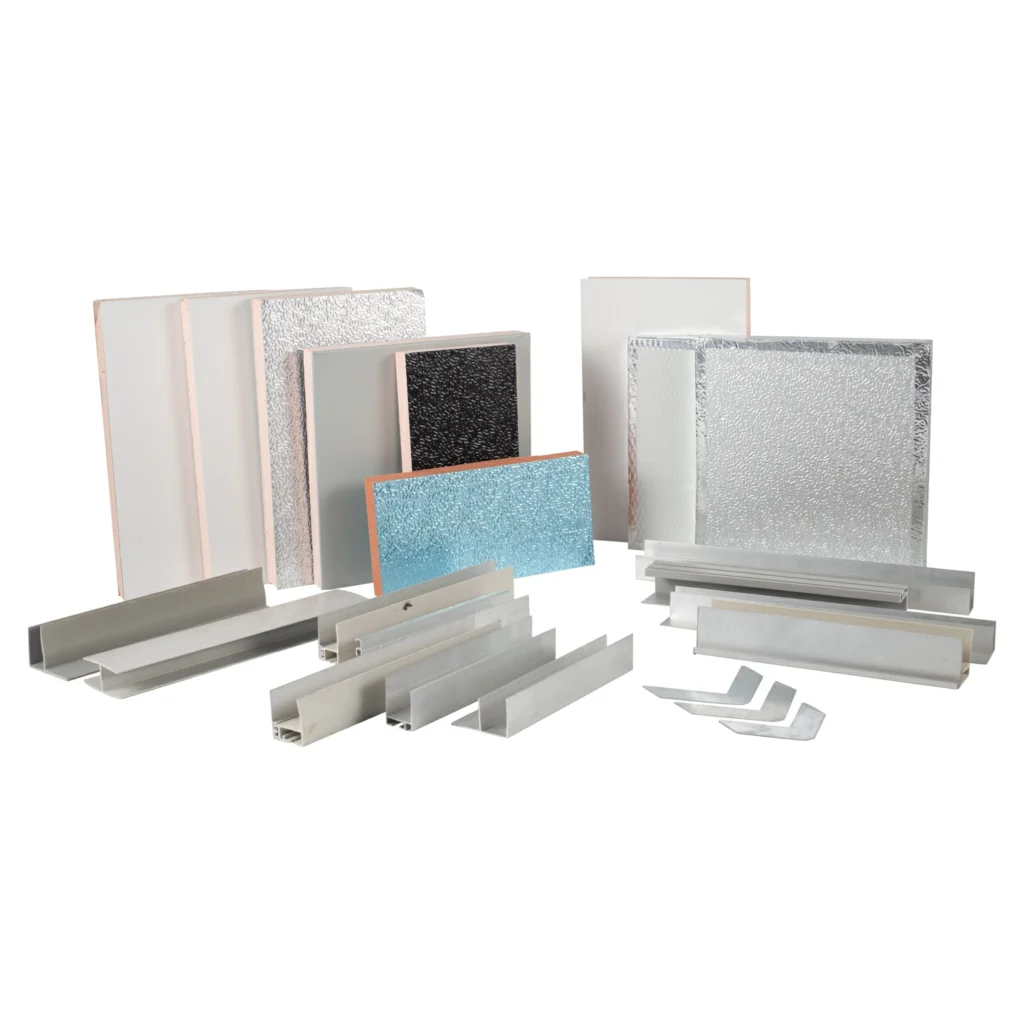

Air conditioning duct board

Phenolic insulation board: closed-cell foam with phenolic resin, flame retardants, smoke suppressants. Benefits: fire protection, thermal insulation.

External wall insulation board

Phenolic insulation board: closed-cell foam with phenolic resin, flame retardants, etc. Key benefits: fire protection, thermal insulation.

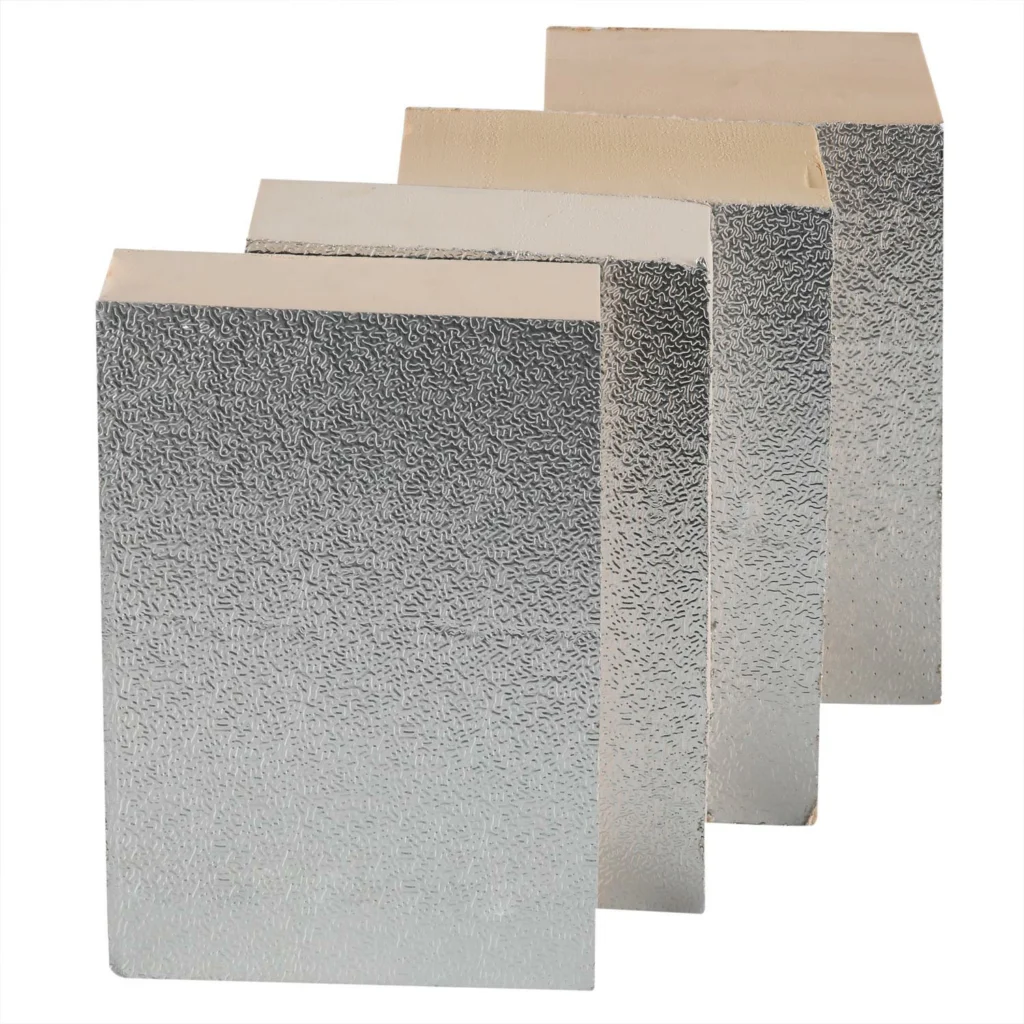

The concept of phenolic insulation board

Phenolic Exterior Wall Panels

Phenolic insulation board is a closed-cell rigid foam made of scientific formula using various substances such as phenolic resin and flame retardants, smoke suppressants, curing agents, foaming agents, and other additives. The most prominent advantages are fire protection and thermal insulation.

| Inspection Items | Technology Index | Inspection Items | Technology Index |

|---|---|---|---|

| Conventional thickness | 30-220mm | Bending strength | ≥1.1 MPa |

| 2000x1200,3000x1200,4000x1200 | |||

| Length/Width (mm) | (or as customized) | Leakage air volume | ≤1.2% |

| Thickness of aluminum foil | 0.025mm, 0.04mm, 0.06mm, 0.08mm | Thermal resistance | 0.86 m2K/W |

| (or as customized) | |||

| Density of core material | 40-60kg/m3 | Smoke density | ≤9, no toxic gas release |

| Water absorption | ≤3.7% | Dimension stability | ≤2% (70±2C, 48h) |

| Thermal conductivity | 0.019-0.02 W(mK) | Oxygen index | ≥45 |

| Heat resistance | -150~+150℃ | Duration of fire resistance | >1.5h |

| Air flow max | 15M/s | Formaldehyde Emission | ≤0.5Mg/l |

| Compression strength | ≥0.18 MPa | Fireproof rating | A2 |

The concept of phenolic insulation board

Phenolic Duct Board

Phenolic insulation board is a closed-cell rigid foam made of scientific formula using various substances such as phenolic resin and flame retardants, smoke suppressants, curing agents, foaming agents, and other additives. The most prominent advantages are fire protection and thermal insulation.

Color steel and aluminum foil

Double sided aluminum foil

Color steel on both sides

Double-sided cement coating

Double-sided galvanized steel

| Inspection ltems | Technology Index | Inspection ltems | Technology Index |

|---|---|---|---|

| Conventional thickness | 20mm,25mm,30mm(As Customized | Bending strength | 21.1 MPa |

| Length/Width (mm) | 2000x1200,3000x1200.4000x1200 (As Customized ) | Leakage air volume | 5 1.2% |

| Thickness of aluminum foil | 0.025mm,0.04mm,0.06mm,0.08mm | Thermal resistance | 0.86 m2K/W |

| Density of core material | 50-65kg/m3 | Smoke density | ≤9, no toxic gas release |

| Water absorption | ≤3.7% | Dimension stability | ≤2% (70+2°℃, 48h) |

| Thermal conductivity | 0.019-0.02 W(mK) | Oxygen index | 245 |

| Heat resistance | -150~+150℃ | Duration of fire resistance | >1.5h |

| Air flow max | 15M/s | Formaldehyde Emission | ≤0.5Mg/L |

| Compression strength | 20.18 MPa | Fireproof rating | A |

Applications:

1.HVAC: Precision-cut foam components, including half-sections, laminates, elbows, and more, with vapor barriers. High-density foam for structural use.

2.Architecture & Construction: Used in roofing, wall panels, insulation, and more. Recognized for exceptional fire protection, expanding market share.

3.Composite Panels: High-density phenolic foam core with steel facings, ideal for various applications like food processing, clean rooms, and cold storage, boasting excellent fire resistance.

4.Process/Petrochemical: Used for pipe, tank, and container insulation in industrial applications.

5.Specialized Use: Fire doors, highly fire-resistant panels, and insulation for ships, offshore structures, and submarines.

Phenolic foam’s development began in the 1990s, initially for military and aerospace use. Later adopted in civil aviation, maritime, and industrial sectors, it’s now prevalent in high-rises, hospitals, and sports facilities due to its fire protection qualities.

Contact WT

renkai@topduct.com.cn

Address

Zhongshan Road, Liangxi District, Wuxi City, Jiangsu Province

Phone

+86 137-7160-1681